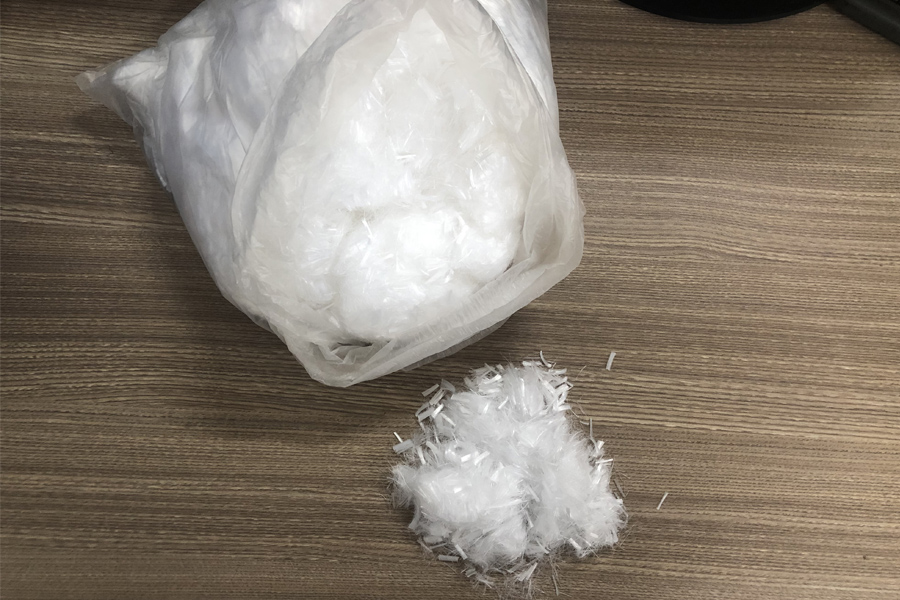

Strong brand XDH Polypropylene fiber bundle is hinged Is developed for steel fiber and alternative products, compared with steel fiber has easy dispersion, easy construction, no damage characteristics of mixing equipment. Coarse polymer fiber is made of polypropylene as raw materials, through special parallel drawing and hinged molding and surface treatment process, high tensile strength, good dispersibility in concrete, bond and strong advantages, can replace steel fiber reinforced cement concrete for cracking.

Polypropylene fiber bundle is hinged Performance parameters:

The fiber bundle is hinged type

The dispersion: high dispersion

The proportion: 0.91g/cm3

The tensile strength of 450Mpa

The elongation: 15%

The initial elastic modulus: 4000Mpa

The melting temperature of 160-170 DEG C

The acid alkali: high

The low temperature of - 75 DEG C: the performance experiment of fiber changes

The safety: non-toxic

The specifications: 19mm, 27mm, 54mm

The packing: 1kg/ bag (customizable).

Polypropylene fiber bundle is hinged Economy:

Compared with steel fiber, corrosion resistance, not easy to wear, with volume 50% price cut crude fiber has the advantages of plastic

Polypropylene fiber bundle is hinged Instructions?

1, dosage: recommended per cubic meter of concrete admixture is not less than 2.7kg (volume ratio 0.3%), adding 5.4kg (volume 0.6%) volume fraction of crude fiber cement and steel fiber is the same as 47kg/m3.

2, length: General cracking enhanced 50mm; added to the shotcrete, the length of not more than 30mm. Avoid the use of more than 50mm specifications.

3, the ratio of design: in general, level without changing the mix parameters of concrete. Considering the requirement of anti cracking performance of concrete, according to the volume ratio of 1:1 and polypropylene reticular fibers with (each side of concrete 0.9kg reticular fiber)

4, choose the mixer: the twin shaft horizontal forced mixer.

5, mixing process: first into the gravel, and then put into the fiber, then sand and stir for 2 minutes, the fiber fully open, and then put the cement and water according to the conventional process of stirring. Also according to the conventional process into the order of the construction, but the mixing stirring time should be no less than 4 minutes, appropriate to extend the time of vibration, in order to make fiber mixing.

6, molding and curing process: no special requirements may extend the vibrating time of about 30 seconds, plaster should be slightly after concrete surface passivation, so as not to bring out the fiber, curing still should be carried out according to concrete requirements

7, packing: standard packing crude fiber 2.7kg package, can be mixed with polypropylene packaging 3.6kg/ bag, can also be packaged according to customer requirements.