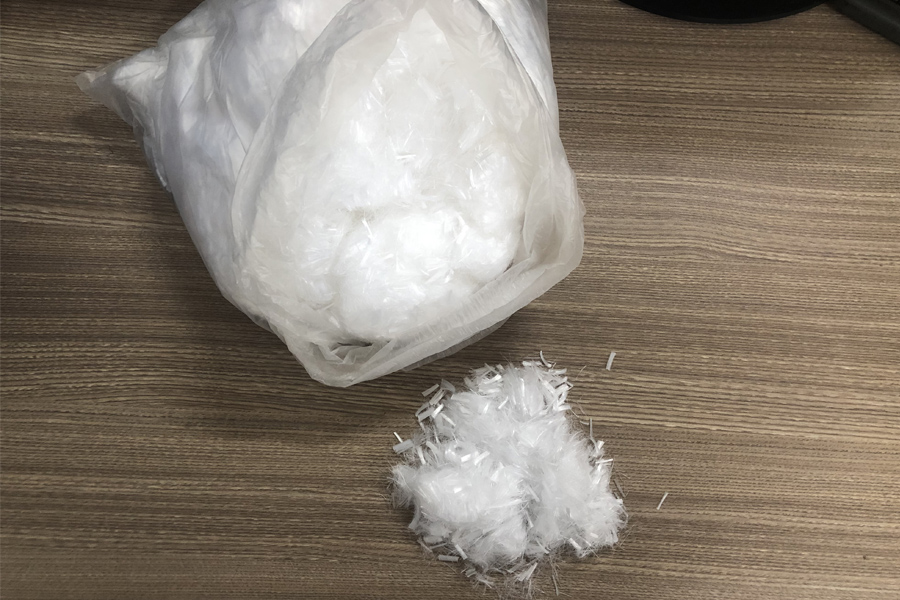

Strong brand XDN Polypropylene fiber mesh With the modified polypropylene as raw material by extrusion, stretching, web forming, surface modification, short process as. The formation of fiber net sheet, in the mixing process of concrete in, Polypropylene fiber mesh Was torn into a two extrusion hook shaped monofilament and mutual multi distribution, enhance the fiber and concrete bonding. A huge number of fibers with a three-dimensional distribution in concrete, provide the mesh supporting role, fundamentally change the concrete crack resistance, impact resistance, fatigue resistance, wear resistance, greatly improve the toughness of concrete and the deformation capacity of concrete engineering quality has greatly improved.

The physical properties of polypropylene fiber mesh

Texture of material | 100% PP | tensile strength | 300~770Mpa |

density | Zero point nine one | Elongation rate | >15% |

length | 10, 15, 19mm | Modulus of elasticity | 3500Mpa |

Dispersion | good | Safety | Non-toxic materials |

Light | 590 C | Acid alkali | strong |

The main function of mesh polypropylene fibre

To improve the anti cracking performance of concrete - mesh polypropylene fibre;

To improve the impact resistance performance of concrete - mesh polypropylene fibre;

The mesh polypropylene fibre concrete / mortar greatly improve the impermeability of waterproof performance;

The polypropylene mesh fiber to improve the concrete frost resistance and temperature resistance performance;

To reduce the brittleness of concrete - polypropylene fiber mesh, improve wear resistance of concrete;

The mesh polypropylene fibre concrete increases fire resistance;

To improve the fatigue strength of sprayed concrete - Polypropylene reticular fiber to improve the pumping performance, reduce the loss of resilience.

The main use of mesh polypropylene fibre

High grade concrete pavement and the fence, bridge, factory floor cracking high requirements engineering can improve the road service life of 5~10 years, and can replace steel wire net;

The overpass, bridge pier, the main structure, which can effectively prevent early cracking, improve component toughness, impact resistance and anti-seismic capacity enhancement;

The bridge main structure and pavement, prevent cracking and to prevent unsafe because of vibration caused by;

Dam, the water conservancy and Hydropower Engineering in reducing spillway and diversion hole parts such as impermeability, require a higher impact resistance of concrete pouring engineering;

The airport runway, tarmac road -- can improve impact resistance and abrasion resistance of pavement cracks and decrease exponentially, due to the rupture of the small pieces of debris, avoid risks caused by the engine intake, improve the safety performance of aircraft;

Shotcrete - tunnel, subway, mine at the top of the wall and slope reinforcement, concrete pump, concrete rebound off, no more than 4%;

The military protection engineering, port, dock, yard, river, can significantly improve the shock resistance and anti fatigue ability, prevent cracking, prevent seepage.

The basement wall, floor and roofing; water channels, water reservoir; septic tank; swimming pool leak.

Recommended dosage of mesh polypropylene fibre

Concrete - usually dosage: 0.9Kg/m3; bridge waterproof layer, recommended dosage: 1.50 Kg/m3.

Using the method of mesh polypropylene fibre

Directly added, does not change the concrete mix in with other mixture before and after filling or adding mixer. Forced stirring time 2~3 minutes for a slightly longer than conventional mixing time, to ensure the uniform distribution of fibers.