Strong brand XDF polypropylene fiber Is a kind of special high performance fiber reinforced concrete / mortar, Polypropylene fiber Can effectively control the micro cracks caused by concrete / mortar plastic shrinkage, dry shrinkage, temperature changes and other factors, to prevent and suppress the formation and development of native concrete cracks, greatly improve concrete / mortar anti cracking impermeability, anti abrasion performance, increase the toughness of concrete, thus improving the service life of concrete. Polypropylene fiber can be widely used in road, fence, bridge deck; dam hydropower project, spillway, diversion hole, water channel; side wall and floor in the basement; industrial and civil building roof, wall, floor, pool, waterproof mortar and cement prefabricated parts; toughening crack, polypropylene fiber is a kind of high performance concrete / mortar impervious material.

Strong brand XDF polypropylene fiber Is the use of modified masterbatch added to polypropylene slices by blending, spinning, stretching and made. Polypropylene fiber after special anti-static and anti ultraviolet treatment, the fiber is uniformly dispersed in the concrete, can play its long-term effect; polypropylene fiber "Y" section increases the surface area of fiber; fiber by chemical and physical modification, porous surface roughness, greatly improving the fiber and cement base set binding material. The performance of fiber by reducing the occurrence and number of primary cracking of concrete to improve the concrete, no conflicts and chemical reaction with concrete aggregate, admixture, admixture, cement will therefore have good adaptability and concrete materials.

Strong brand XDF polypropylene fiber Mechanism of action

Cement concrete in the hardening process, hydration reaction of the cement with water, caused by concrete shrinkage, in the later due to the evaporation of free water in concrete caused by shrinkage, the shrinkage stress tensile strength will exceed the cement matrix to produce micro cracks in concrete. The development of micro cracks about 70% is completed in 3-7d gel period, when the concrete tensile strength less than 1MPa. Join the tough series of concrete mortar in concrete with fibers, the fibers can easily quickly and evenly distributed in the concrete to support the formation of a chaotic system, the directional dispersion of the concrete stress, prevent the occurrence and development of primary cracks in concrete, the number and scale to eliminate or reduce the original micro crack, greatly improving the concrete anti crack infiltration capacity, improve the toughness of concrete, thus prolonging the service life of concrete. In addition because the fiber itself has a certain strength, fiber dispersion and the formation of anchoring effect in concrete, its destruction must absorb energy in an instant.

Strong brand XDF polypropylene fiber physical property

Texture of material | 100% PP | density | 0.91g/cm Three |

Line density | 7.5~18.5 dtex | Fracture strength | More than 300Mpa |

melting point | 165~175 C | Light | 590 C |

length | 6, 8, 12, 19mm | elongation at break | 15%~20% |

Cross sectional shape | Type Y | Equivalent diameter | 0.033~0.048mm |

acid and alkali resistance | strong | Anti aging | good |

Strong brand XDF polypropylene fiber major function

- improve crack resistance;

- improve impermeability;

- improve the impact resistance and abrasion resistance;

- improve the frost resistance;

To improve the toughness;

- increase the fire resistance of the concrete, improve the antiknock function;

To improve the quality of concrete products.

Strong brand XDF polypropylene fiber Use the recommended

The concrete structure of basement

Applicable scope: the basement floor and side wall, roof, pool, drainage, sewage treatment pond rigid waterproof concrete structure.

The outer wall plastering cement mortar

Applicable scope: plastering wall; lightweight wall (aerated concrete block) plastering; fine stone concrete rigid waterproof layer.

Strong brand XDF polypropylene fiber Usage method

The dosage range: 0.6~1.2Kg/m Three . Usually concrete admixture:: 0.9 Kg/m Three Mortar: 1.2, Kg/m Three .

- Length: Concrete: 15~19 m m; 8~12 m m; mortar, putty: 3~6 m M.

The mixer type: General for slurry type mixer.

The mixing process: before or after the mixture is filled, or loaded at the same time.

The stirring time: under normal circumstances, the stirring time unchanged or slightly longer. Extended mixing does not affect the fiber dispersion and fiber strength, will not cause fiber group.

The mix design: fiber strengthening effect is the physical process, does not need to increase the amount of water in the concrete mix, or change the ratio of ingredients.

- maintenance: adding polypropylene fiber, no special maintenance requirements, only according to the original standard.

The surface of postprocessing: fiber reinforced concrete, fiber surface does not affect any treatment and coating.

Strong brand XDF polypropylene fiber Performance review

The raw material for the test

cement | Golden cat P.O32.5 |

sand | The Yangtze River sand fineness modulus of 2.6 |

Gravel | The nominal size of 5mm~25mm granite |

fly ash | A gray level |

admixture | JM-IV superplasticizer |

fibre | Produced by the company leade type XD-F, XD-N, monofilament fiber mesh, the specifications for the 19mm, 408Mpa and 360Mpa respectively. The fracture strength, elongation is greater than 15% |

Strong brand XDF polypropylene fiber Test mix: (kg/m Three )

cement | fly ash | sand | stone | water | JM-IV | fibre |

Blank concrete | Four hundred and twenty | Sixty | Six hundred and sixty-three | One thousand and eighty-two | One hundred and seventy-five | Seven point two |

sfrc | Four hundred and twenty | Sixty | Six hundred and sixty-three | One thousand and eighty-two | One hundred and seventy-five | 7.2 0.9 |

Strengthening concrete mortar special fiber on properties of concrete

Strong brand XDF polypropylene fiber Use method and matters needing attention

1. mortar crack resistance, impermeability putty and other appropriate selection of field equivalent diameter of thin filament fiber, fiber length according to the aggregate degree to determine reasonable, large aspect ratio is conducive to the strengthening and toughening effect of fiber, the smaller the ratio of length to diameter for fiber dispersion. The putty with fiber length is 3 mm, with 5-10 mm fiber mortar, mortar sand when the particle size is 5 mm when you use the 12-25 mm fiber, when the concrete stone size up to 20 mm can be used 19-55 mm reticular fiber.

2. when used with fiber aggregate simultaneously into the blender, but to prevent the fiber aggregation between mixing blade and the baffle block. Usually, the stirring time was extended, adding to the coarse aggregate dispersion fiber, aggregate impact to elastic and reticular fiber tearing open become chaos to the single fiber distribution, but long mixing time will affect the fiber strength.

3. due to the addition of fibres will make the concrete slump and slump down. If the slump can not meet the construction requirements, should the appropriate use of plasticizer or water reducing agent to improve the slump, to meet the requirements of construction.

4. construction and maintenance as ordinary concrete, no special requirements.

5. can be used as structural reinforcement materials, can not replace the reinforcing material alone is used to solve the structural subsidence and cracking by strong external shock situations.

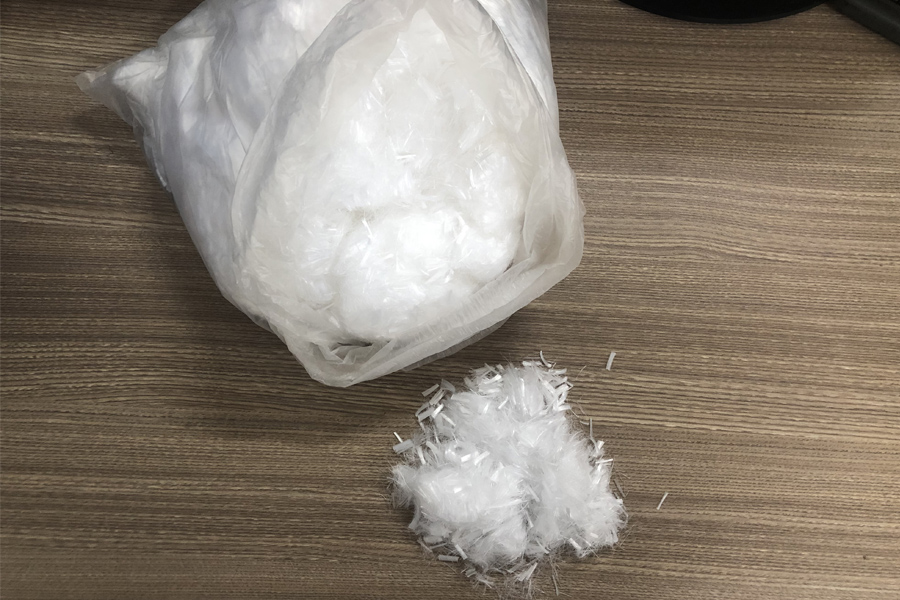

Product packaging

One is the use of PE bags, 0.9 kg per bag, packaging for plastic bags; the other one is water soluble paper bags, 0.9 kg per bag, carton for outer packing. A small package, according to customer requirements packaging.